Features

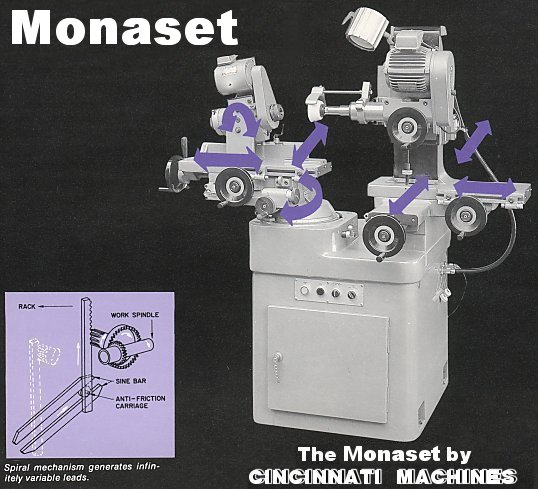

CMI’s MONASET Tool Grinder precisely grinds, sharpens, and reconditions parts with complex shapes…

We looked at our successful MONASET grinder very closely before we came up with the engineering refinements which, when combined with its field proven concepts, make it an even better tool for sharpening, reconditioning, or making small cutters from solid stock.

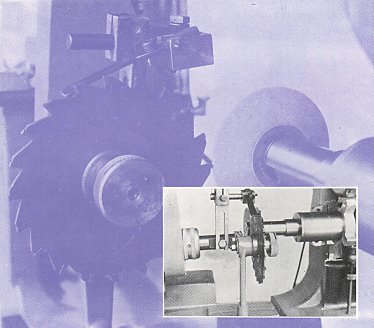

Here, for example, are the proven features that MONASET retains: Its capability for multiple grinding operations at a single chucking of the work-piece-saves setup time; assures excellent concentricity. MONASET still maintains its versatility for generating straight or tapered, right or left-hand, infinitely variable leads from a simple built-in lead mechanism.

Turntable mounting of entire workhead slide assembly, adjustable through 235 plus degrees in the horizontal plane, has proven to be a real asset when grinding radii.

Workhead that is adjustable on separate main slide with dual handwheel control has proven to be a boon for setups. Offset slide for workhead spindle permits centerline of spindle to be offset from center of turntable-a necessity when grinding convex or concave radii with centerline outside the axis of workpiece.

And micrometer stop dogs and graduated dials which greatly simplify accurate positioning of workhead main slide, and wheelhead cross and longitudinal slides.

Standard Equipment

Extra Cost Equipment

15. Internal grinding attachment.

I6. Collet-‘1/4″-for internal grinding attachment chuck.

17. Large cutter radius grinding attachment.

18. Four-inch universal three-jaw chuck for workhead, (Adjust-tru type).

19. Additional index plates for spiral lead indexing unit.

20. Additional diamond truing tool with diamond nib.

21. Additional straight cylindrical collets.

Specifications

Capacity

Workhead:

Swing over main slide, max dia………………………….. 12″ (304mm)

Collet work dia, max……….. 1.25″ (31mm) min………. 0.12″ (3mm)

Lead generated by spiral lead mechanism, min………..1.81″ (45mm)

Length between spindle noseand tail center, max……..6″ (152mm)

Wheelhead

Grinding Wheel dia. max…………………………………….4″ (101mm)

Range

Workhead:

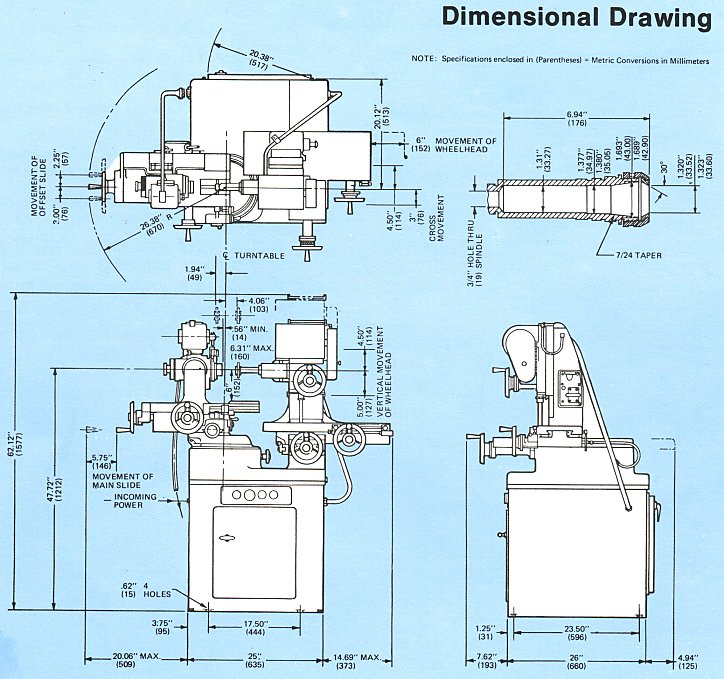

Main slide travel………………………………………………..5.75″ (146mm)

Offset slide travel, total……………………………………….5.25″ (133mm)

– front of center, 3″ (76mm)

– Rear of center, 2.25″ (57mm)

Workhead angular adjustment:

Horizontal plane (turntable base)…………………………..235 degrees

Vertical plane,

– above center…………………………………………………40 degrees

– below center…………………………………………………40 degrees

Wheelhead:

Longitudinal slide travel………………………………………6″ (152mm)

Vertical slide travel, total…………………………………….9.50″ (241mm)

– above center, 4.50″ (114mm)

– below center, 5″ (127mm)

Cross slide travel, total………………………………………7.50″ (190mm)

– front of center, 3″ (76mm)

– Rear of center, 4.50″ (114mm)

Spindle Speeds

(±0%,-8% variation allowable)

Workhead, one speed………………………………………436 RPM

Wheelhead, three speeds………………………………….4000, 5729 and 8000 RPM

(motor speed @ 3600 rpm)

Internal Grinding Attachment (Extra Cost) three speeds ………..16410,23510, and 32820 (approx.)

Motors, Electric

Workhead drive, AC ……………. includes reverse 1/4 hp (.186 kilowatts)

Wheelhead drive, AC ………………………………….1/2 hp (.373 kilowatts)

Floor Space Weight

Area of base only…………………………………………………………………………25″ x 26″ (635mm X 660mm)

Area required for machine (including swivel and overtravel movements)………60″ X 67″ (1524mm X 1701mm)

Height from floor to center of workhead spindle …………………………………..47.72″ (1212mm)

Height, overall with wheelhead raised………………………………………………..62.12″ (1577mm)

Netweight (including motors and controls)………………………………………….1525 Ibs (691 kilograms)

Dimensional Drawing

Pricing

MONASET by Cincinnati Machines: Tool & Cutter Grinder – Including the following equipment:

1. Set of (7) Grinding Wheels: Straight, cup, flared and recessed for general purpose grinding requirements.

2. Set of (5) Grinding Wheel Collets. (4) standard and (1) extension collet.

3. Set of (4) Index plates for Spiral Lead Mechanism 0, 8, 10, & 12 divisions.

4. Grinding Wheel Guards with extensin bar.

5. Wheelhead Toothrest Assembly with extension bar

6. Tooth rest Centering Gauge.

7. Adjustable Tailstock Support Unit.

8. Diamond Holder Bracket and Front Stock Support.

9. Adjustable Quartz-Halogen work lamp.

10. Set of Wrenches: allen, double-end, & spanner.

11. Parts list manual.

PRICE COMPLETE – F.O.B. Cincinnati Ohio……………………………………..$ Call

Monaset XL as above but with Ball Screws & Turcite B Lined Ways FOB Cincinnati $Call

OPTIONAL EQUIPMENT

1. 17 Piece Collet Set “A” & “C”

2. Large Cutter Radius Grinding Attachment

3. 4″ Universal 3-Jaw Chuck for the Workhead

4. 3 Piece Additional Index Plates (of the standard size 8,10, & 12)

5. Index Plates (specify umber of notches)

6. Diamond turning Tool with Diamond Nib

7. 1/2″ Bore Grinding Wheel Flange

8. Spring Loaded Index Paul

9. Standard Size “A”/”C” Collet (each)

10 Special Size “A”/”C” Collet (each)

11. Brown & Sharpe #5,7,9 Collet Set

Call for a quote on any of the above Optional Equipment

Prices may vary due to supplier sources.