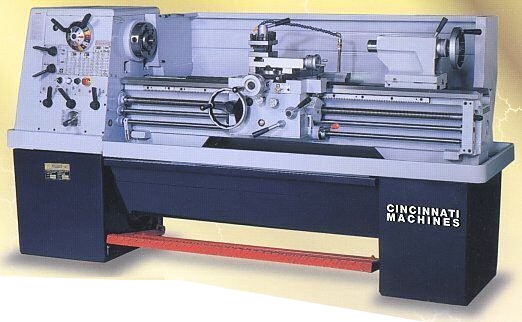

SMALL TO MEDIUM SIZE LATHES

Base Features for all COBRA High Performance Engine Lathes

- GAP BED, FLOOD COOLANT, DUAL DIALS, 110 VOLT CONTROL SYSTEM, 4 WAY TOOLPOST, THREAD INDICATOR, CENTER AND CENTER SLEEVE, LEVELING BOLTS, SERVICE TOOLS AND TOOLBOX, INSTRUCTION AND PARTS MANUAL.

- STANDARD EQUIPMENT ON THE 18″, 20″ AND 22″ MACHINES INCLUDE THE “MATRIX” CLUTCH SYSTEM FOR ENGAGING THE SPINDLE DRIVE.

- INDUCTION HARDENED AND GROUND BEDWAYS.

- HARDENED AND GROUND SPINDLES & GEARS IN HEADSTOCK.

- CAMLOCK SPINDLE NOSE PROVIDES FAST & SAFE MOUNTING.

- AN INTERLOCK DEVICE TO PREVENT SIMULTANEOUS ENGAGEMENT OF FEED ROD AND LEADSCREW.

- NO VOLTAGE RELEASE, LOW VOLTAGE CONTROLS, AND FOOT BRAKE PROVIDES SAFETY OPERATION.

- TOTALLY ENCLOSED OIL BATH, DOUBLE WALL APRON WITH SPLASH TYPE LUBRICATION.

- FORWARD-OFF-REVERSE SPINDLE CONTROL PROVIDED BY GATED LEVER AT APRON.

- VARISPEED LATHES EQUIPPED WITH ALL DIGITAL, HIGH PERFORMANCE AND LOW NOISE INVERTERS.

13″ X 40″ High Performance Gap Bed Engine Lathe

- THE SPINDLE SPEEDS CHANGED BY COMBINED LEVER WITH SELECT KNOB FOR EXACT AND SMOOTH OPERATION.

- TOTALLY ENCLOSED NORTON GEARBOX WITH OIL BATH FOR LUBRICATING THROUGHOUT. THE SELECT KNOBS FOR SMOOTH AND RAPID GEAR CHANGES.

- AVAILABLE FOR WHITWORTH AND METRIC THREAD CUTTING WITH CONVERSION CHANGE GEARS.

- ALL THE FEEDS ARE CONTROLLED BY TWO PUSH/PULL PLUNGERS AT APRON FOR EASY AND FAST OPERATION.

- THE OPTIONAL EQUIPMENT “UNIVERSAL GEARBOX” PROVIDES A COMPREHENSIVE RANGE OF METRIC, WHITWORTH, D. P. AND MODULAR THREADS.

- THE FEED ROD AVAILABLE TO FIT OVERLOAD CLUTCH AS OPTIONAL EQUIPMENT.

- OPTIONAL EQUIPMENT TWO-SPEED MOTOR FOR 16 SPINDLE SPEEDS.

- THE VS MODELS ARE EQUIPPED WITHYASKAWA VARISPEED-606 PC3 (2.2KW) ULTRA-COMPACT, ALL-DIGITAL, LOW-NOISE INVERTERS OR EQUIVALENT.

1440VS – 14″ X 40″ High Performance Gap Bed Engine Lathe

- TOTALLY ENCLOSED UNIVERSAL GEARBOX PROVIDES A COMPREHENSIVE RANGE OF METRIC, WHITWORTH, D. P. AND MODULAR THREADS.

- BUILT-IN LONGITUDINAL AND CROSS FEED EXCHANGE OPERATED BY PUSH/PULL PLUNGER ON APRON.

- FEED ENGAGE LEVER OPERATED BY PULL-UP, AND DISENGAGE OPERATED BY PUSH-DOWN TO ENSURE EXACT AND FAST OPERATION.

- THE FEED ROD OVERLOAD CLUTCH IS STANDARD EQUIPMENT.

- THE VS MODELS ARE EQUIPPED WITHYASKAWA VARISPEED-606 PCS (3.7KW) ULTRA-COMPACT, ALL-DIGITAL, LOW-NOISE INVERTERS OR EQUIVALENT.

15″ X 50″ High Performance Gap Bed Engine Lathe

- ALL GEAR. 16 SPINDLE SPEEDS IN GEOMETRIC PROGRESSION AT 25-2000 R.P.M.

- SLIDEWAY LUBRICATION PROVIDED BY “ONE-SHOT” PLUNGER TYPE PUMP.

- TOTALLY ENCLOSED UNIVERSAL GEARBOX PROVIDES A COMPREHENSIVE RANGE OF METRIC, WHITWORTH, D. P. AND MODULAR THREADS.

- ADJUSTABLE CLUTCH ON APRON PROVIDES LONGITUDINAL AND CROSS FEED PRESSURE ADJUSTMENT.

- CROSS SLIDE NUT INCORPORATES BACKLASH ELIMINATOR.

- THE VS MODELS ARE EQUIPPED WITH YASKAWA VARISPEED-616G3 (5.5KW) HIGH-PERFORMANCE, LOW-NOISE, GENERAL-PURPOSE INVERTERS OR EQUIVALENT.

- GEARED HEAD MACHINE AVAILABLE WITH OPTIONAL MATRIX CLUTCH.

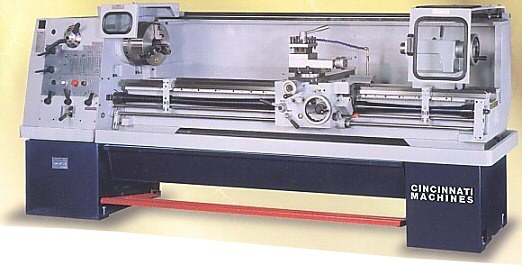

18, 20, 22 Swing High Performance Gap Bed Engine Lathe

- ALL GEAR HEAD. 16 SPINDLE SPEEDS IN GEOMETRIC PROGRESSION FROM 20-1600 R.P.M.

- SLIDEWAY LUBRICATION PROVIDED BY ” ONE-SHOT ” PLUNGER TYPE PUMP.

- TOTALLY ENCLOSED UNIVERSAL GEARBOX PROVIDES A COMPREHENSIVE RANGE OF METRIC, WHITWORTH, D.P. AND MODULAR THREADS.

- ADJUSTABLE CLUTCH ON APRON PROVIDES LONGITUDINAL AND CROSS FEED PRESSURE ADJUSTMENT.

- BUILT-IN FEED REVERSE OPERATED BY PUSH/PULL PLUNGER ON APRON.

- WIDE, FULL LENGTH CROSS SLIDE EXTERNALLY DOVETAILED FOR QUICK AND EASY MOUNTING OF ACCESSORIES.

- CROSS SLIDE NUT INCORPORATES BACKLASH ELIMINATOR.

- THE “MATRIX” MECHANICAL MULTI-PLATE CLUTCH IN THE HEADSTOCK PROVIDES FORWARD-NEUTRAL-REVERSE CONTROL.

- THE VS MODELS ARE EQUIPPED WITH YASKAWA VARISPEED-616G3 (7.5KW) HIGH-PERFORMANCE, LOW-NOISE, GENERAL-PURPOSE INVERTERS OR EQUIVALENT.

Specifications

| Center Height | ||||

| Swing over bed | ||||

| Swing over cross slide | ||||

| Swing in gap | ||||

| Bed length between centers | 100″bed 120″bed |

|||

| Gap width in front of faceplate | ||||

| Spindle nose (camlock) | ||||

| Headstock spidle bore | ||||

| Headstock spidle bore taper | ||||

| Number of Spindle speeds | ||||

| Range of spindle speeds RPM | ||||

| Optional RPM | ||||

| Varispeed RPM (gear steps) | RPM |

|||

| Width of bed | ||||

| Length of bed | 100″bed (145″) 120″bed (165″) |

|||

| Cross slide travel | ||||

| Compound travel | ||||

| Tailstock spindle travel | ||||

| Tailstock quill taper | ||||

| Tailstock quill diameter | ||||

| No. of English Threads | 36 optional |

|||

| Range of English Threads T.P.I. | 4-72 T.P.I. |

|||

| No. of Metric Threads | 31 Optional |

|||

| Range of Metric Threads | ||||

| No. of Diametral Pitch Threads | ||||

| Range of DP Threads | (optional) |

|||

| No. of Module Pitch Threads | ||||

| Range of Module Pitch Threads | ||||

| Longitudinal Feeds | 0.02-0.520mm/rev. (Optional) |

|||

| Cross Feeds | 0.006-0.170 in/rev. (Optional) |

|||

| Main Motor | 3 / 1.5 HP (Optional 2 Speeds) |

5 / 5 HP (Optional 2 Speeds) |

||

| HP – Varispeed | ||||

| Packing Sizes: | ||||

| Length | 100″bed (160″) 120″bed (180″) |

|||

| Width | ||||

| Height | ||||

| Net Weight (lbs) | 20″ 4840,5500,6600,7700 22″ 5280,5940,7040,8140 |

|||

| Gross Weight (lbs) | 20″ 5500,6270, 7480, 8800 22″ 5940,6710, 7920, 9240 |

Optional Accessories

“Bison” 3-jaw lathe chuck

“Bison” 4-jaw lathe chuck

Chuck Guard

Worklights

Faceplate

Steady Rest

Follow Rest

Micrometer Bed Stop

Taper Turning Attachment

Quick change toolpost w/4 holders

“Royal” 5C lever collet attachment

5C collet set 1/16 -1 1/16 x 64ths

5C collet set 1/16 -1 1/16 x 32nds

5C collet set 1/16 -1 1/16 x 16ths

Universal Gearbox

2 Speed Motor

Main Spindle Clutch

Optional 12HP Motor

Increase in pricing for Variable Speed on the 18″, 20″, 22″ (Must be factory installed)

2 Axis Digital Readouts

Acu-Rite DRO 200T

Newall Topaz